I've been in the midst of identifying a suitable material for the project and have come up with Accoya, an artificially modified wood that is durable, sustainable and highly resistant to exterior conditions including UV damage and insect attack. I contacted a representative and they were highly interested in the design and are willing to grant a sponsorship deal, however the materials that they are able to supply are only suitable for the roof pieces only. The seat pieces are far too large for the use of Accoya.

As a result, we will most likely be using Accoya for the roof pieces only depending on a number of factors including the cost and the shipping time (Accoya is located in England).

Another material that I have found; densified wood, appears to be much more suitable for the seat segments. These materials are available in 1000mm x 2000mm x 120mm thick sheets which is more than enough for what the project demands. The material is also available in Sydney unlike Accoya. We may end up using densified wood for the roof section as well depending on the outcome.

I have also completed the calculation of the number of pieces and the rough dimensions. There are a total of 129 pieces in the design of which, 87 comprise the seats and 42 make up the roof canopy.

The connection design for the seats is well under-way however we have little idea on how the roof comes together. The roof pieces themselves are significantly larger than the seats and are very thin. Fabricating them out of one solid piece is most likely out of the option as we would need a CNC bed capable of machining a 1880mm x 1400mm piece and there would also be a lot of materials wastage.

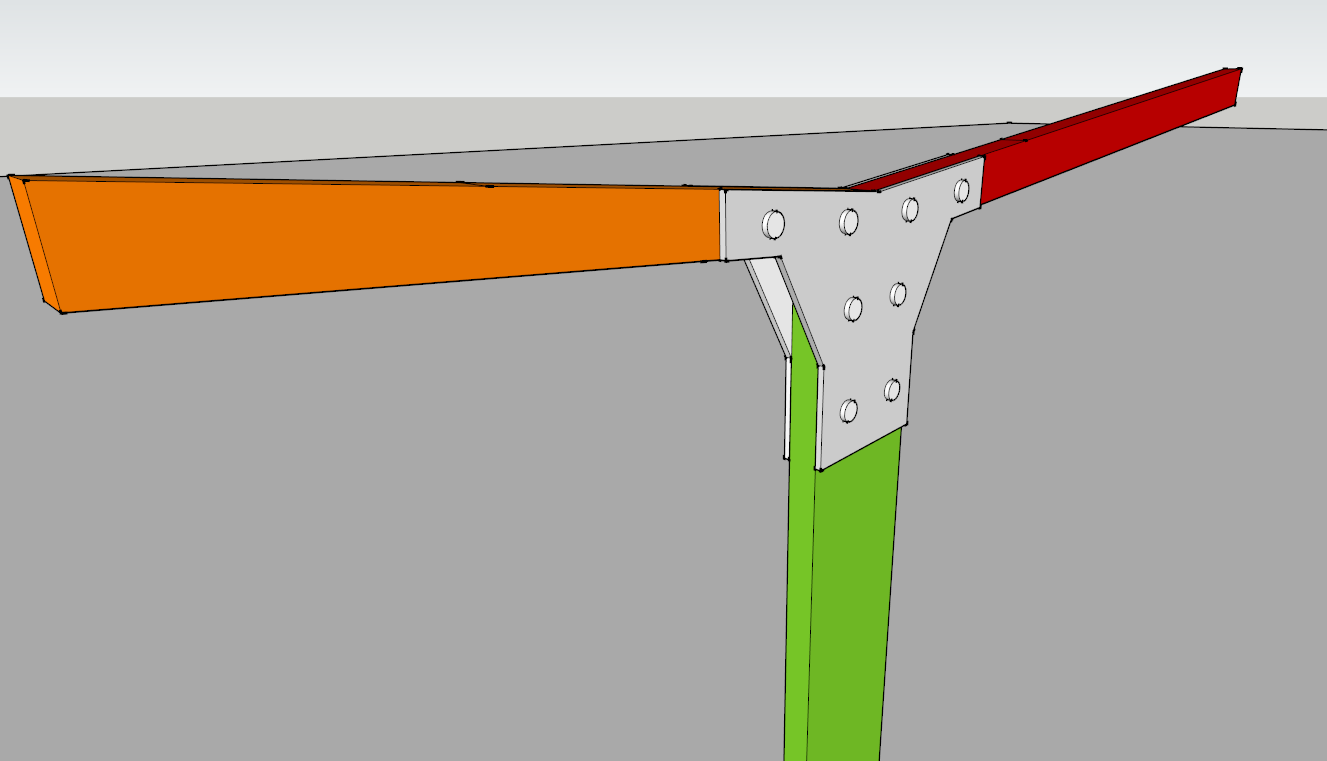

Instead, I've created a design that allows a roof segment to be constructed out of 5 pieces.

The pieces consist of:

1 vertical piece

1 large overhang piece

1 small overhang piece

and two 6mm thick metal plates fixing them all together.

I have since emailed John Carrick, a certified Engineer and Architecture lecturer at UNSW to critique this idea and give feedback on it's feasibility.

No comments:

Post a Comment